Products

3000 tons to 4500 tons clamping force die casting machine

Brand:

LansonItem No.:

LS3000 - LS4500Product origin:

China| ITEM | Unit | LS3000 | LS3500 | LS4000 | LS4500 |

| Clamping Force | kN | 30000 | 35000 | 40000 | 45000 |

| Clamping Stroke | mm | 1500 | 1600 | 1800 | 1900 |

| Ejector Force | kN | 900 | 900 | 1000 | 1000 |

| Ejector Stroke | mm | 300 | 300 | 350 | 400 |

| Die Height (Min.-Max.) | mm | 800-2000 | 850-2000 | 900-2100 | 900-2100 |

| Platen Size(HxV) | mm | 2620X2620 | 2780X2780 | 2800X2800 | 3000X3000 |

| Space Between Tie Bars(HxV) | mm | 1650X1650 | 1750X1750 | 1850X1850 | 1950X1950 |

| Injection Force(with intensification) | kN | 1950 | 2410 | 2410 | 2710 |

| Injection Stroke | mm | 1200 | 1400 | 1400 | 1600 |

| Plunger Diameter | mm | 150-190 | 160-200 | 160-200 | 180-220 |

| Injection Weight | kg | 39.8-63.8 | 52.7-82.4 | 52.7-82.4 | 76.3-114.0 |

| Casting Pressure(with intensification) | MPa | 110-68 | 120-77 | 120-77 | 117-78 |

| Casting Area | cm2 | 2725-4410 | 2910-4540 | 3330-5190 | 3850-5770 |

| Max.Casting Area (40MPa) | cm2 | 7500 | 8750 | 10000 | 11250 |

| Shot Injection Position(below center line) | mm | –250,–450 | –300,–600 | –300,–600 | –300,–600 |

| Plunger Penetration | mm | 550 | 600 | 600 | 700 |

| Diamater Of Pressure Chamber Flange | mm | 280 | 320 | 320 | 340 |

| Height Of Pressure Chamber Flange | mm | 30 | 35 | 35 | 35 |

| Hydraulic Working Pressure | MPa | 16 | 16 | 16 | 18 |

| Hydraulic Oil Tank Capacity | L | 4500 | 4800 | 5100 | 5500 |

| Machine Dimensions(LxWxH) | mm | 15000X5200X5200 | 15800X5400X5300 | 16500X5450X5400 | 17300X5570X5420 |

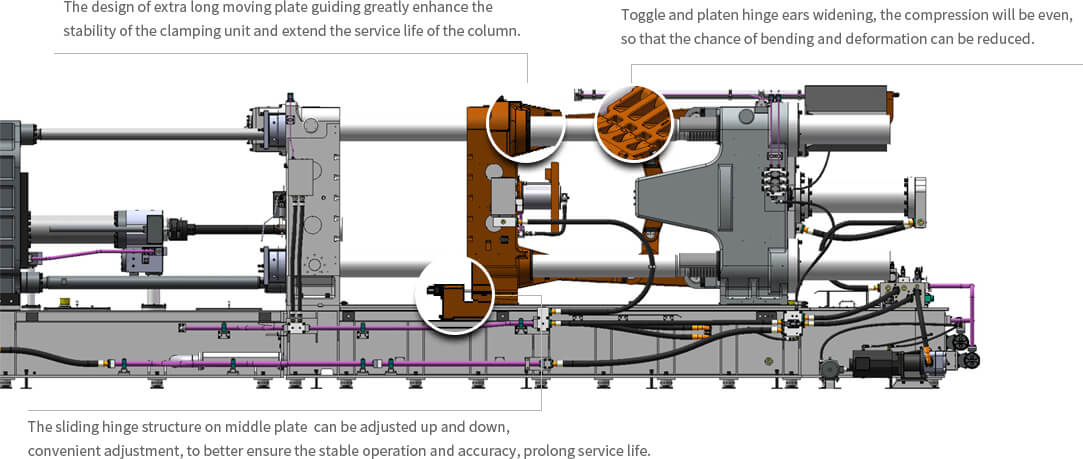

Clamping system

1)Increase the die-cut space design to accommodate larger molds.

2)Larger mold clamping margin design, more effective to meet customer needs.

3) Template thickened design, more rigid.

4) The patented die-casting machine has a large-bar thread dustproof and waterproof structure to improve the stability and service life of the column.

5) The unique clamping hydraulic system combines the characteristics of the elbow mechanism to ensure high response, high efficiency and high safety.

6) Extremely short mode-locked return path minimizes back pressure and increases system speed.

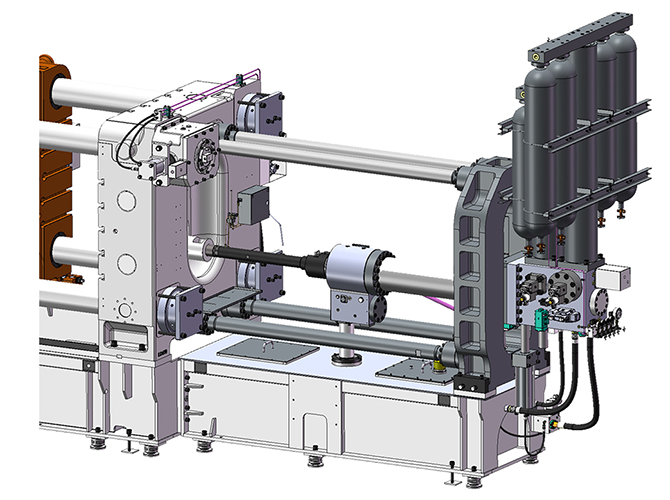

Injection system

1)The energy is added to the large design, the energy is sufficient, the system pressure drop is reduced, the injection repeatability is high, and the pressure and speed are more stable.

2)The injection valve plate adopts an integral design, which is completed in one process to ensure the accuracy and stability of the injection.

3)Equipped with independent energy storage function to shorten energy storage time and improve efficiency.

4)The drawbar is boldly designed to ensure rigidity and template parallelism, boosting and injection level in the same direction layout structure, and improve the stability of the injection system.

5)Advanced injection system performance: maximum air injection speed > 8m / s, boost pressure time: pressure time <20ms (large machine), pressure time <15ms (small machine).

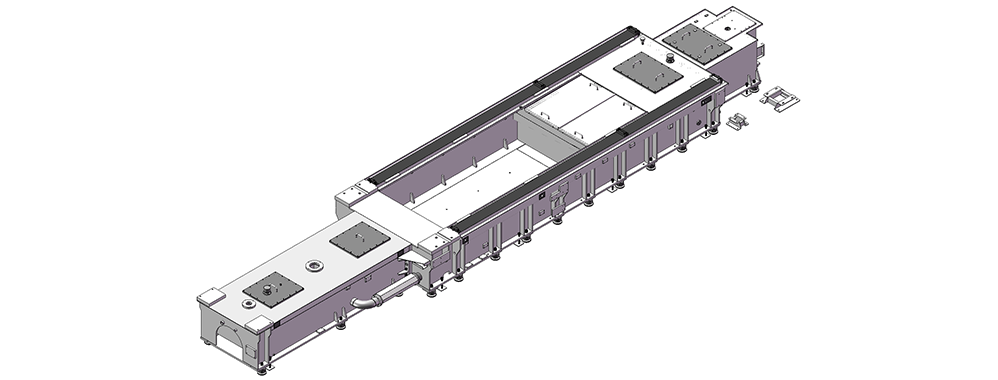

Rack system

1)It adopts double-strength balance structure, adopts annealing to eliminate welding stress treatment, reasonable force, small frame deformation, and multiple horizontal detection points on the frame to facilitate the adjustment of the horizontal level of the frame.

2)The frame adopts a monolithic structure to reduce the vibration of the clamping oil circuit board, and the arrangement is reasonable, simple, and the stability is better, and the subsequent detection and maintenance are convenient.

3)The original three-box fuel tank separates the return oil from the oil, the oil flow is reasonable, and the stability of the oil circuit control is improved.

4)The pipelines are distinguished by color, which is both beautiful and can prevent the risk of confusion during the use of the customer.

5)The pipeline design uses a large number of hoses to absorb vibration shocks effectively; the steel pipes are fixed by heavy-duty plastic pipe clamps, and the high-pressure hoses are equipped with explosion-proof chains.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

New Products

© Copyright: 2025 Lanson Precision Intelligence Equipment Technology Co., Ltd All Rights Reserved.