Products

PET plastic injection moulding machine is suitable for producing preforms applied in bottles, beverage industry, food packaging industry and cosmetic industry, etc.

Brand:

LansonItem No.:

GM2-LS160SPET to GM2-LS480SPETProduct origin:

ChinaClamping Force (tons):

160T to 480TPower System:

servo systemShot Weight (PET gram):

554.2 - 3392.9Shot Volume (cm3):

513 - 3142Product Advantages:

GM2-PET series is suitable for producing preforms applied in bottles, beverage industry, food packaging industry and cosmetic industry, etc.

The excellent plasticizing of GM2-PET guarantees the cycle time of the preform products.

L/D ratio of 24:1 screw design, effectively control injection stroke comparing with the same level traditional PET preform machine, also improves the injection volume. This kind design is good for reducing material accumulation, durable and easy-to-clean.

High efficiency servo energy saving system

Using upgraded servo system, low operation noise, strong power, fast response, guarantees low energy consumption, reduces production cost.

Professional PET screw and barrel

Special 24:1 PET screw and barrel design ensures the high quality plasticizing performance, which highly improves product efficiency and avoids traditional PET molding defects, such as bubble, crazing, discoloration, etc.

Double layer barrel cover that perfectly protect operator and heater bands

Enlarged ejector force and ejector stroke satisfy the production demands for perform

Equipped with multiple sets of large water manifold, improves the mold cooling, which ensures crystallization of products. (Different model different quantity). We will make different type and quantity of water manifold according to customer requirement.

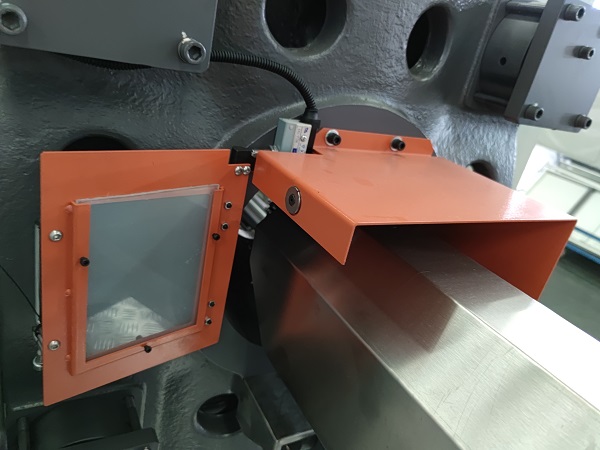

Nozzle cover with sensor

Safety and protect the operator

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

© Copyright: 2026 Lanson Precision Intelligence Equipment Technology Co., Ltd All Rights Reserved.