Products

Product features : Higher rigidity, higher strength, faster response, lower friction, Energy saving servo system.

Brand:

LansonItem No.:

GT-LS1000SProduct origin:

ChinaClamping Force (tons):

1000tonPower System:

servo systemShot Weight (PS gram):

4137Shot Weight (PP gram):

3723Shot Volume (cm3):

4546Remarkable Advantages:

Higher rigidity, lower friction, faster response and more energy saving servo system

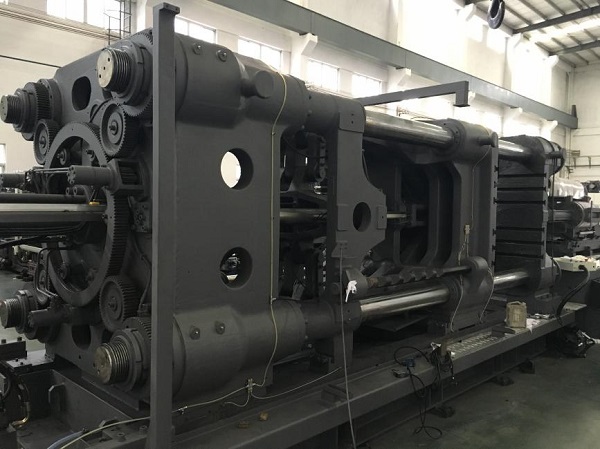

Higher performance Injection Unit (1000 ton plastic injection molding machine)

Double injection unit design with two cylinder carriers, Injection unit with linear guide way, upgraded features including feeding loader

Strengthen Injection Unit Base

Higher Rigidity clamping unit

Stronger casting, higher rigidity, running more stable.

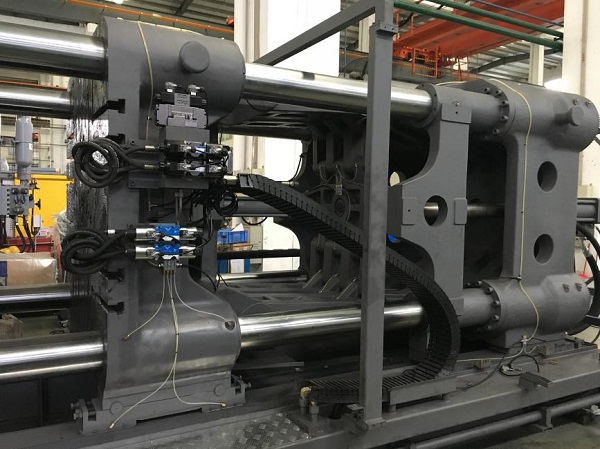

Supporting platen and trunks

Stronger clamping unit system, the powerful supporting platen for cross head and rear platen is higher rigidity, it makes the mold opening and closing smoothly.

Wires are into cable chain, more tidy and longer life time.

Strong mold adjusting nuts

Mold adjusting nuts equipped with rigidity bearings which gives more smooth movement and helps with lower friction, for better movement and longer life.

Rotatable Techamtion controller system

Faster response controller with rotatable design, convenient for the operator controlling the computer position easily.

Servo system

More Energy saving consumption, lower noise. It can save up to 30% - 55% energy compare with variable pump design.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

© Copyright: 2026 Lanson Precision Intelligence Equipment Technology Co., Ltd All Rights Reserved.