Products

High Speed Plastic Injection Molding Machine -- Specialized for Thin wall packaging industry, disposable fast food/ice cream containers, bowl, flower pot, bucket, cutlery, mobile phone covers, cell phone case etc.

Brand:

LansonItem No.:

GT3-LS280BTProduct origin:

ChinaClamping Force (tons):

280BTPower System:

Servo SystemShot Weight (PP gram):

185Shot Volume (cm3):

256Product Advantages: FAST

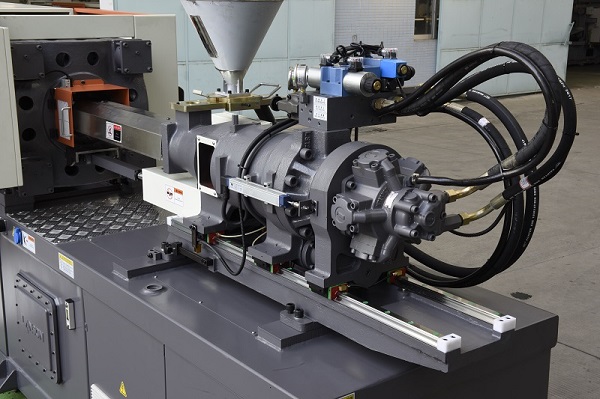

GT3-BT series high speed plastic injection molding machine upgraded with advanced single injection cylinder design one complete casting part. It is perfect for high speed and self-innovated & patented by Lanson, It features precision hydraulic circuit, fast response, high efficiency and energy saving. Easier for thin wall packaging industry, fast food/ice cream containers, disposable cup,cutlery, bowl, flower pot, mobile phone covers, cell phone case etc.

Achieved 30 self patents nationally.

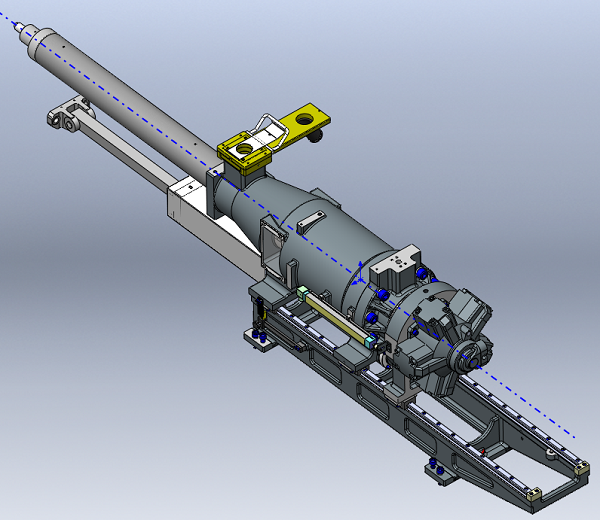

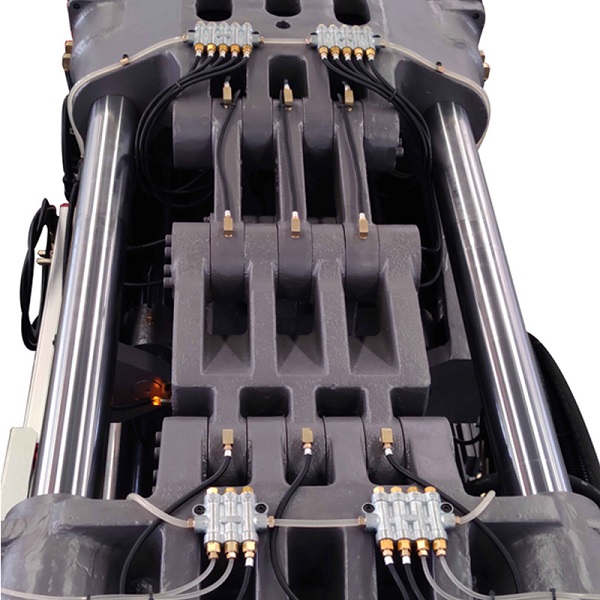

Single Injection Cylinder

Co-axial with screw & plasticizing motor, increase the injection pressure and speed. Have a fast and accurate injection performance. More efficient injection performance, more compact design, higher injection pressure, for more sophisticated injection product. Low friction hydraulic design, minimize the injection resistance, fast response, ultra speed, more energy saving.

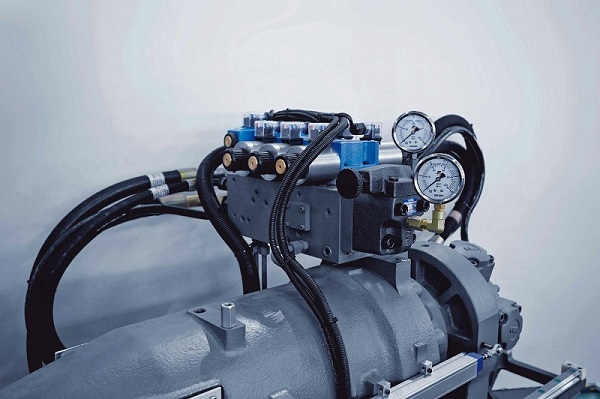

Injection action connect with control valve rigidity

Effective decrease fluid fluctuation and increase injection precision

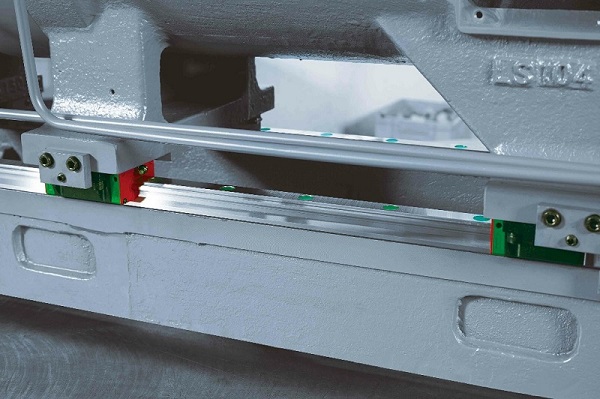

Injection unit linear guide way

Accurate, low friction, fast response, good repeat-ability and energy saving.

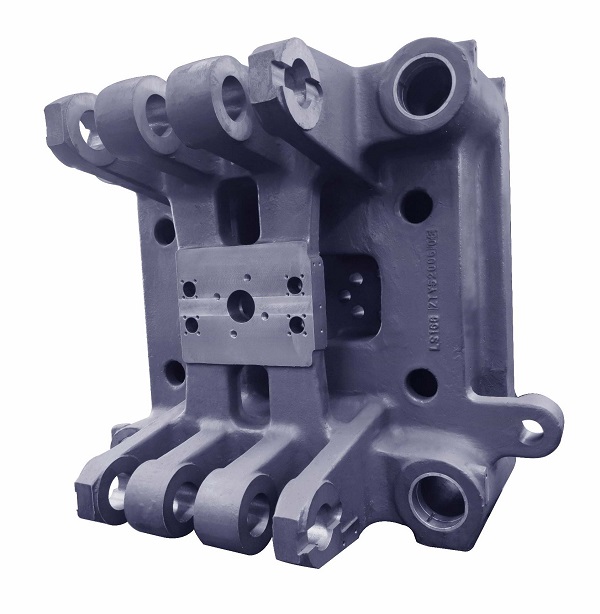

Thicken stronger platens & tie bar

Optimised platen design distributes stresses evenly for higher parts quality

Strong toggles with longer service life

Increased and Widened hinge ears

Stress received by molding platen is dispersed equally and avoid stress concentration by widen hinges on moving platen.

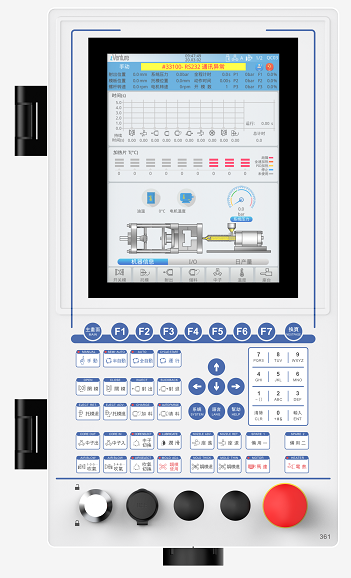

Upgraded 10 inch Professional control system

Advanced 10 inch EST control system, which function is control sensitive and precise, intelligent optimization mold open and close movement curve, manufacturing management, fault diagnosis and so on.

Infrared Ray Heaters

Better control the barrel temperature and achieve high performance injection production.

Enlarged servo system double servo system

Faster responses for higher repeatability, control precision and energy efficiency.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

© Copyright: 2026 Lanson Precision Intelligence Equipment Technology Co., Ltd All Rights Reserved.